- Home

- Products

- Microscope

- Accessories for Microscope

Description

Application

Features

Specifications

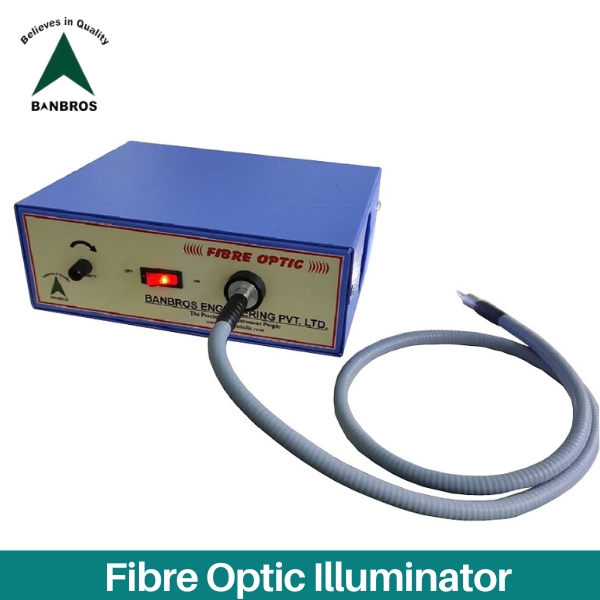

| Model No. | BFO-250 |

| Illumination | LED bulb 50 W |

| Controls | On / off and intensity controllers SMPS based |

| Cooling | By turbine type silent fan, noiseless and vibration free |

| Power Input | AC 220 – 240, 50 Hz Single Phase |

| Fiber Optical Cord | Length- 1100mm, Diameter- 7mm |

| Dimensions | 175 x 175 x 125 |

| Weight | 3.5 kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Fibre Optic Illuminator

Description

Application

Features

Specifications

Accessories

Software Description

Download Cataloge

ENQUIRY

Ring Light

Description

Application

Features

Specifications

Accessories

Software Description

Download Cataloge

ENQUIRY

Eyepiece

Description

BMEX-Series can be easily inserted into eyepiece tube of microscope. The Digital Micro-Image Displays Immediately on computer or notebook PC. This camera ranges is an ultra-high performance CMOS camera and it adopts ultra-high performance CMOS sensor as the image-picking device. USB2.0 is used as the data transfer interface. The camera hardware resolutions range from 2M.P, 5M.P, 12M.P and comes with the Integrated zinc aluminium alloy compact housing. It comes with advanced video & image processing application ultracam; providing Windows/Linux/OSX multiple platform SDK; Native C/C++, C#/VB.NET, DirectShow, Twain Control API. It can be widely used in bright-field light environment and microscope image capture and with moderate frame rate.

It can provide support for detail image demonstration and analysis/application, including following function:

- Take Photo and Save Picture into Computer

- Take Video and Save Video into Computer

Application

Features

Specifications

| Model No. | BMEX-2F | BMEX-5F | BMEX-12F |

| Sensor | CMOS 1/2.9 inch | CMOS 1/2.8 inch | CMOS 1/2.3 inch |

| Pixels | 1920 x 1080 pixels, 2.0 MP | 2560 x 1920 pixels, 5.0 MP | 4000 x 3000 pixels, 12.0 MP |

| Scan mode | Progressive, rolling shutter | Progressive, rolling shutter | Progressive, rolling shutter |

| Pixel size | 2.8 μm x 2.8 μm | 2.0 μm x 2.0 μm | 1.33 μm x 1.33 μm |

| Max fPs |

Up to 30 FPS (1920x 1080 pixels) |

Up to 30 FPS (2560 x 1920 pixels) Up to 50 FPS(1600 x 1200 pixels) |

Up to 15 FPS (4000x 3000 pixels) |

| Filter | RGB |

RGB |

RGB |

| Mount | C-mount | C-mount | C-mount |

|

Grayscale conversion |

8 bits |

8 bits |

8 bits |

| Color depth | 24 bits | 24 bits | 24 bits |

|

Exposure |

Automatic or manual, from 1 ms to 2s |

Automatic or manual, from 1 ms to 2s |

Automatic or manual, from 1 ms to 2s |

| White balance | Automatic/manual | Automatic/manual | Automatic/manual |

|

Dynamic range |

72 db |

72 db |

60 db |

| Sensitivity V/lux-sec | (at 550 nm) 0.51 | (at 550 nm) 2.0 | (at 550 nm) 1.5 |

|

Data interface |

USB 2.0 at 480 Mb/s |

USB 2.0 at 480 Mb/s |

USB 2.0 at 480 Mb/s |

| Operation humidity | 10-85 % humidity | 10-85 % humidity | 10-85 % humidity |

|

Operating temperature |

0 to 60°C |

0 to 60°C |

0 to 60°C |

| Supplied with | 0.45x objective with C-mount, USB 2.0 cable, 30 and 30.5 mm adapters for stereo microscopes, 76 x 24 mm calibration slide, CD ROM with Image Focus Plus software, carton box | ||

| Software | Windows 7 and higher (32 and 64 bit configurations). A Mac OS software version is also supplied | ||

Accessories

Software Description

Download Cataloge

ENQUIRY

Industrial Digital USB Microscopic Camera

Description

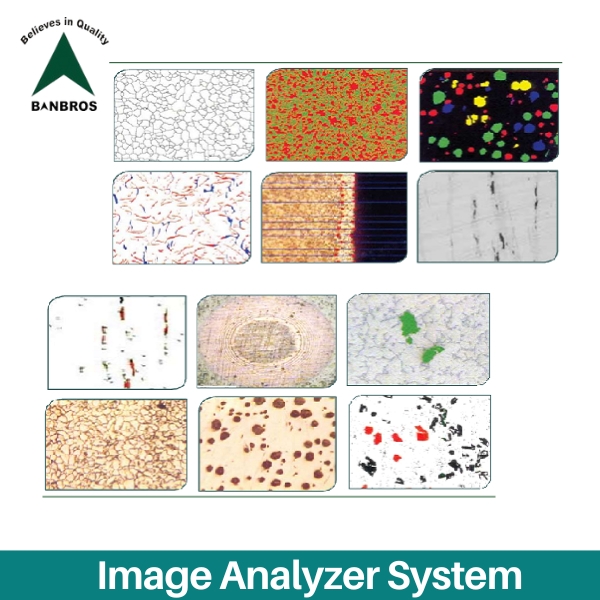

Grain Size Estimation

- With automatic grain boundary re-construction Analyzer can take any ordinary / practical image for processing. It cleans the same, automatically joins the broken grain boundaries and makes the image perfectly suitable for further automatic analysis. Does not call for manual intercept marking

- Options exist for intercept method (parallel lines or concentric circles depending on the aspect ratio of grains), planimetry method, comparison method. Also results can be obtained in the form of grain size distribution, individual grain area, its perimeter, L/ D ratio, mean lineal intercept length, average grain size, largest grain size in microns etc

- Grain size analysis of ceramic, Copper and other materials can bedetermined as per the individual method.

Phase analysis

Based on the gray level difference as many phases can be identified and measured to its fine perfection based on thresholding gray levels. With automatic and manual methods histograms can be generated

Application

Features

Specifications

Accessories

Software Description

MICROSTRUCTURE ANALYZER SOFTWARE

-

Grain Size Estimation

-

Phase analysis

-

Nodularity analysis

-

Flake analysis

-

Particle count and size classification

-

Linear Measurements

-

Inclusion analysis

-

Multilayer coating measurement (Tribology)

-

Other module

Download Cataloge

ENQUIRY

Image Analyzer System