- Home

- Products

- Sample Preparation Equipment

- Specimen Grinding And Polishing Machine

Description

Our BP-1 SERIES Metallography specimen polishing machine is suitable for the polishing of the specimen which has been roughly grinded. The specimen surface turns out very smooth with mirror like finish after polishing and can be used to observe and measure the metallography structure and other inspections of specimen under microscope. Silicon carbide paper or Red velvet cloth both, any of the one can be used on this model of ours.

Application

Features

Specifications

| Model No. | BP-1 | BP-1(V) | BP-1(VD) |

| Diameter of Polishing disc | 200mm | ||

| Rotating disc mode | Fixed | Variable | |

| Rotating disc speed | 960 RPM | 50-1250 RPM | |

| Motor specifications | 180W ( A.C ) | 180W ( D.C ) | |

| Display type | - | - | LED |

| Digital display | - | - | 7 segments |

| Power source | 220 Volts 50 Hz | ||

| Dimensions | 320x320x300mm | ||

| Weight | 18 Kgs (Approx.) | ||

Accessories

Software Description

Download Cataloge

ENQUIRY

Single Disc Metallographic Specimen Grinding & Polishing Machine

Description

Our BP-2T SERIES Metallography specimen polishing machine is a kind of double disc table top type polishing machine and can be operated by two persons at the same time. It is suitable for the polishing & grinding of the specimen. The specimen surface turns out to be very smooth with a mirror like finish after polishing and can be used to observe and measure the metallography inspection of specimen under microscope. Fibre reinforced plastic ( FRP ) body makes the machine light weight and easy to be installed for use in laboratories, institutes and quality section of various industries.

Application

Features

Specifications

| Model No. | BP-2T | BP-2T(V) | BP-2T(VD) |

| Diameter of Polishing disc | 200mm | ||

| Rotating disc mode | Fixed | Variable | |

| Rotating disc speed | 960 RPM | 50-1250 RPM | |

| Motor specifications | 180W ( A.C ) | 180W ( D.C ) | |

| Display type | - | - | LED |

| Digital display | - | - | 7 segments |

| Power source | 220 Volts 50 Hz | ||

| Dimensions | 720x490x320mm | ||

| Weight | 38 Kgs (Approx.) | ||

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Metallographic Specimen Grinding & Polishing Machine

Description

BP-3T SERIES Metallography specimen polishing machine with fixed/variable rotating speed is a kind of triple disc table type polishing machine. It is suitable for the polishing & grinding of the specimen. The specimen surface is very smooth after processing and can be used to observe and measure the metallography structure of specimen under microscope. Machine body is made of MS powder coated.

Application

Features

Specifications

| Model No. | BP-3T | BP-3T(V) | BP-3T(VD) |

| Diameter of Polishing disc | 200mm | ||

| Rotating disc mode | Fixed | Variable | |

| Rotating disc speed | 900 RPM | 50-900 RPM | |

| Motor capacity | 1/2 HP DC | ||

| Motor specifications | 180W ( A.C ) | 180W ( D.C ) | |

| Display | - | - | Digital display RPM meter |

| Power source | 220 Volts 50 Hz | ||

| Dimensions | 90 x 50 x 92 cm | ||

| Weight | 43 Kgs (Approx.) | ||

Accessories

Software Description

Download Cataloge

ENQUIRY

Triple Disc Metallographic Specimen Grinding & Polishing Machine

Description

Model BP-2G is a cabinet type metallography specimen polishing machine. This machine features nice appearance design, big store cabinet and cooling system (which can clear up the heat produced during grinding so as to prevent the metallography structure from being damaged).

By equipping the motor with variable rotating speed, it can meet the different demands of different materials when polishing. It is the ideal specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

Specifications

| Model No. | BP-2G | BP-2G(V) |

| No. of Polishing disc | Double | |

| Diameter of polishing disc | 200mm | |

| Rotating disc type | Fixed | Variable |

| Polishing disc rotating speed | 900 rpm | 50-900 rpm |

| Motor | 2x80W 220V 50Hz. | |

| Net weight | 43 Kgs | |

Accessories

Software Description

Download Cataloge

ENQUIRY

Cabinet Type Metallographic Specimen Grinding & Polishing Machine

Description

MBP Series Metallographic Specimen grinding & polishing machine is equipped with single disc and features stepless speed changing grinding and polishing.

The rotating speed of grinding and polishing disc is adjustable from 50 to 1000 rpm. It can realize the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing.

This machine features easy operation and economical applying. It is the ideal specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

Specifications

| Model No. | MBP-1B |

| No. of Polishing Disk | Single |

| Diameter of polishing disk | 200mm |

| Diameter of grinding disk | 230mm |

| Display of Rotating Speed | Digital Display |

| Rotating Disk Type | Variable |

| Polishing disk rotating speed | 50â€1000 RPM |

| Motor | 550W 220V 50Hz |

| Dimensions | 65 x 37 x 31 cm |

| Net weight | 43 Kgs |

Accessories

Software Description

Download Cataloge

ENQUIRY

Single Disc Metallographic Specimen Grinding & Polishing Machine

Description

MBP Series Metallographic Specimen grinding & polishing machine is equipped with single disc and features stepless speed changing grinding and polishing.

The rotating speed of grinding and polishing disc is adjustable from 50 to 1000 rpm. It can realize the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing.

This machine features easy operation and economical applying. It is the ideal specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

Specifications

| Model No. | MBP-2B |

| No. of Polishing Disk | Double |

| Diameter of polishing disk | 200mm |

| Diameter of grinding disk | 230mm |

| Display of Rotating Speed | Digital Display |

| Rotating Disk Type | Variable |

| Polishing disk rotating speed | 50â€1000 RPM |

| Motor | 550W 220V 50Hz |

| Dimensions | 690 X 715 X 310mm |

| Net weight | 45 Kgs |

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Metallographic Specimen Grinding & Polishing Machine

Description

MBP-2BP Metallographic specimen grinding & polishing machine is equipped with double disc and features stepless speed changing grinding and polishing.

The rotating speed of grinding and polishing disc is adjustable from 50 to 1000 rpm. It can realize the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing.

This machine features easy operation and economical applying. It is the ideal specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

Specifications

| Model No. | MBP-2BP |

| No. of Polishing disc | Double |

| Polishing head | With polishing head |

| Diameter of polishing disc | 200mm |

| Diameter of grinding disc | 230mm |

| Display of rotating speed | Digital display |

| Rotating disc type | Variable |

| Polishing disc rotating speed | 50-1000 RPM |

| Motor | 550W 220V 50Hz |

| Dimensions | 690 X 715 X 310mm |

| Net weight | 45 Kgs |

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Metallographic Specimen Grinding & Polishing Machine with Polishing Head

Description

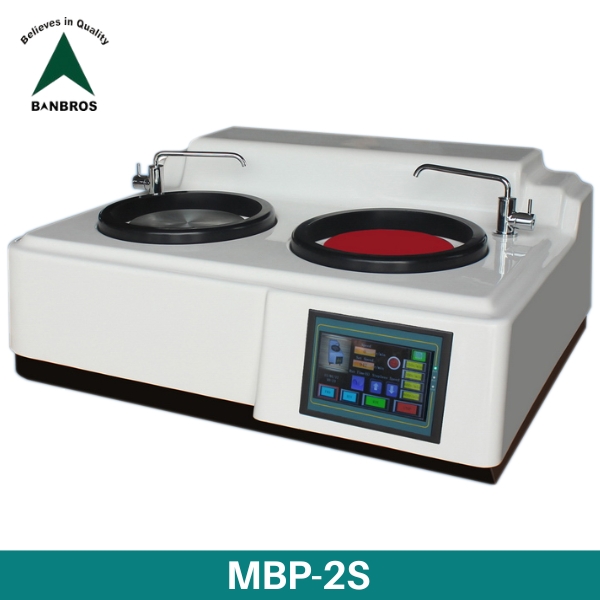

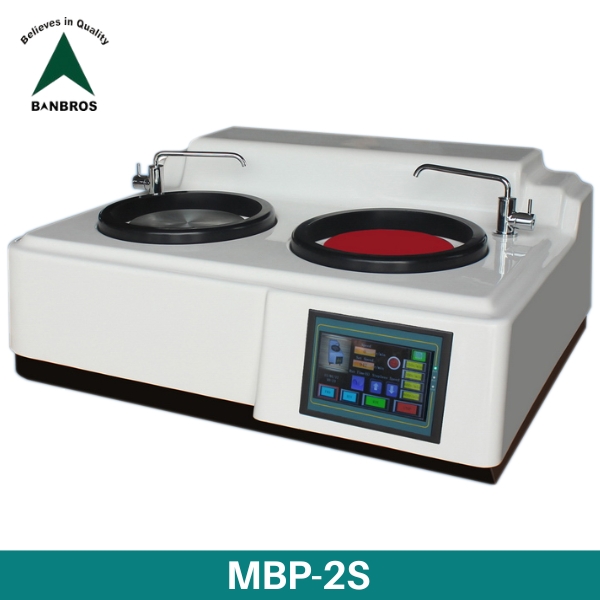

MBP-2S is a newly designed touch screen type metallographic specimen grinding and polishing machine which is equipped with double discs and features stepless speed changing. It can realize the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. This machine features easy operation and economical applying. It is the ideal specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Double grinding & polishing discs

- Touch type LCD screen operation. Rotating speed is displayed on LCD directly.

- Grinding and polishing time is adjustable from 0 to 1000 seconds

- There are two working conditions for this model: the stepless speed changing status or four-level constant speed status. The working condition can be switched from one to another easily.

- The rotating direction of working disc can be chosen at will.

- Four-level constant speed: 150, 300, 600, 800 rpm.

- Stepless speed changing from 50 to 1000 rpm.

- This model is designed and manufactured as per international advanced specimen preparing technology.

- Equipped with beautiful appearance machine shell and stainless steel parts which never rust.

Specifications

| Model No. | MBP-2S |

| No. of Polishing Disk | Double |

| Diameter of polishing disk | 200mm/250mm |

| Rotating speed of working disk | 50-1000 rpm ( stepless speed changing) or 150 /300/600/800rpm ( four-level constant speed) |

| Power supply | Single phase, 220V, 50Hz |

| Motor power | 550W |

| Dimensions | 870 X 760 X 560 mm |

| Net Weight | 45 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Touch Screen Double Disc Metallographic Specimen Grinding & Polishing Machine

Description

Model METAPOL 1000 Metallographic specimen grinding and polishing machine is equipped with single disc and features stepless speed changing and three-level constant speed for grinding and polishing. The working time can be preset and the rotating direction can be controlled. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Stepless speed changing of 50-1000 rpm, and three-level constant speed of 300, 600 and 900 rpm.

- Working time presetting.

- FWD and REV rotating direction control.

- Quick exchanging disc. The working disc can be changed and replaced swiftly.

Specifications

| Model No. | BETAPOL-1000 |

| No. of Grinding & Polishing Disc | Single |

| Diameter of working disc | 250mm ( 203mm) |

| Rotating speed of working disc | stepless speed changing 50-1000 rpm, and three-level constant speeds of 300 / 600 / 900 rpm |

| Working time pre-setting | 5-360 minutes |

| Grinding & Polishing Disc Direction | Clockwise or anticlockwise |

| Power supply | Single phase, 220V, 50Hz |

| Motor power | 550W |

| Dimensions | 730 x 450 x 370 mm |

| Net weight | 35 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Single Disc Metallographic Specimen Grinding & Polishing Machine

Description

Model BETAPOL-1000X Automatic Metallographic specimen grinding and polishing machine is equipped with automatic polishing head and features stepless speed changing and three-level constant speed for grinding and polishing. The working time can be preset and the rotating direction can be controlled. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- 7” Large touch screen operation.

- Six pieces Φ30mm samples can be grinded and polished simultaneously.

- Both grinding disc and polishing head adopt stepless speed control, and the rotating direction of grinding disc can be shifted.

- Electric central force holding, fix the sample and then it can complete the whole process of grinding and polishing, and this can ensure the plane parallelism of sample.

- The loading force can be adjusted during running process.

- Working time presetting

- Quick exchanging disc. The working disc can be changed and replaced swiftly.

Specifications

| Model No. | BETAPOL-1000X |

| No. of Grinding & Polishing Disc | Single |

| Grinding & Polishing Disc Diameter | 250mm ( 200mm is optional) |

| Rotation Speed of working disc | Stepless speed changing 50-1000 rpm, and three-level Constant speeds of 300/600/900 rpm |

| Rotating speed of polishing head | Stepless speed changing 5-100 rpm |

| Sample holder | Φ30mm, 6-hole (or customized) |

| Sample preparing time | 60-999 seconds |

| Pressure range | 5-170N |

| Power supply | Single phase, 220V, 50Hz |

| Input power | 700W |

| Dimensions | 730 x 450 x 900 mm |

| Net weight | 65 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Single Disc Automatic Metallographic Specimen Grinding & Polishing Machine with Polishing Head

Description

Model BETAPOL 2000X Automatic Metallographic specimen grinding and polishing machine is equipped with automatic polishing head and features stepless speed changing and three-level constant speed for grinding and polishing. The working time can be preset and the rotating direction can be controlled. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Double grinding & polishing discs

- Six pieces Φ30mm samples can be grinded and polished simultaneously.

- Both grinding disc and polishing head adopt stepless speed control, and the rotating direction of grinding disc can be shifted.

- Electric central force holding, fix the sample and then it can complete the whole process of grinding and polishing, and this can ensure the plane parallelism of sample.

- The loading force can be adjusted during running process.

- Working time presetting

- Quick exchanging disc. The working disc can be changed and replaced swiftly.

Specifications

| Model No. | BETAPOL-2000X |

| Diameter of working disc | 250mm (200mm or 300mm is optional) |

| Rotating speed of working disc |

stepless speed changing 50-1000 rpm, and three-level constant speeds of 300 / 600 / 900 rpm FWD & REV rotating directions can be switched |

| Rotating speed of polishing head | stepless speed changing 5-100 rpm |

| Sample holder | Φ30mm, 6-hole (or customized) |

| Sample preparing time | 60-999 seconds |

| Pressure range | 5-170N |

| Power supply | Single phase, 220V, 50Hz |

| Motor power of main machine | 750W |

| Motor power of polishing head | 20W (may be customized 200W) |

| Dimensions | 980 x 920 x 900 mm |

| Net weight | 86 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Automatic Metallographic Specimen Grinding & Polishing Machine

Description

Model BETAPOL-2200S Metallographic specimen grinding and polishing machine is equipped with double discs and features stepless speed changing for grinding and polishing. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. By adjusting the transducer, it can realize the rotating speed of grinding and polishing disc adjustable from 50 to 1000 rpm. This bring this machine with much more extensive applying and make it become the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Stepless speed changing 50â€1000 rpm

- CCW and CW rotating direction control

- Quick exchanging disc

Specifications

| Model No. | BETAPOL-2200S |

| No. of Polishing Disk | Double |

| Diameter of polishing disk | 200mm |

| Rotating speed of working disk | Stepless speed changing 50-1000 rpm (other speeds are optional) |

| Power supply | Single phase, 220V, 50Hz |

| Input power | 550W |

| Dimensions | 870 x 760 x 560 mm |

| Net weight | 56 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Metallographic Specimen Grinding & Polishing Machine

Description

Model BETAPOL 2250X Metallographic specimen grinding and polishing machine is equipped with double discs and features stepless speed changing for grinding and polishing. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing.

Application

Features

- Multi-usage, metallographic specimen of coarse grinding, fine grinding, coarse and fine polishing, one machine to complete.

- Grinding disc diameter: 250 mm, compare to ordinary grinding disc, effective area increased by 60%

- Manual mode: three-level constant speed mode and variable speed mode

- Three level constant speeds: customer can define three common speeds for pregrinding, grinding and polishing

- Variable speed mode: grinding speed 100-1000 R/min

- Automatic mode: Eight sections programmable control, automatically stop, convenient for customer getting metallographic sample

- Easily replace magnetic antiâ€sticking dish, can make all kinds of sample of coarse and fine grinding, coarse and fine polishing all process

- Optional work disc rotating direction: clockwise and counterclockwise are optional

- By using the electromagnetic valve to control the water on and off

- Increase the automatic grinding head, can be upgraded to automatic polishing machine, automatic processing of six samples at the same time

- Beautiful outlook and good quality

Specifications

| Model No. | BETAPOL-2250X |

| No. of Polishing Disk | Double |

| Diameter of polishing disk | 250mm (Optional 230mm, 200mm) |

| Rotating speed of working disk | Stepless speed changing 100-1000 rpm (rotating direction exchangeable) |

| Three level constant speed V1=300rpm, V2=500rpm, V3=800rpm (or customizable) | |

| Power supply | 750W, 220V, 50/60Hz |

| Input power | 750W |

| Dimensions | 730×700×350mm |

| Net weight | 50 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Double Disc Metallographic Specimen Grinding & Polishing Machine

Description

Application

Features

- Multi-usage, one machine to complete the whole process of metallographic rough grinding, fine grinding, rough polishing and fine polishing.

- Single point pneumatic holding, no need for sample clamping.

- Six pieces of Φ30mm samples can be polished simultaneously.

- PLC independent control for the grinding disc and grinding head. The grinding & polishing parameters like rotation speed, grinding & polishing time, rotation direction, water valve on/off etc. can be set and automatically saved, easy to call.

- Large touch screen interface, convenient for parameter setting, intuitive state display and easy operation.

- Stepless speed changing for both grinding disc and grinding head. The rotation direction is switchable between FWD & REV.

- PLC control for water supply and grinding material dispenser.

- Working mode:

- Automatic mode: According to the sample materials user’s habits, 30 groups of processes can be set and called. Each process can contain 10 steps of process parameters (each process is corresponding to certain grinding or polishing process. Process parameters: rotation speed of grinding disc and polishing head, grinding and polishing time, etc.)

- Manual mode: According to each grinding and polishing process, 30 groups of process parameters can be set and called: grinding disc and polishing head rotation speed, grinding and polishing time, water supply on/off etc.

- Setting mode: Set certain function of equipment separately.

- The water supply can be controlled by electromagnetic valve. There is automatic water cleaning device under grinding disc and it can clean the inside wall automatically.

- Grinding head automatic electromagnetic lock, no need for manual locking handle.

- Multi-language interface is available.

- High accuracy, stable running, low noise.

- Grinding & polishing dispenser is optional.

- Operation by mobile remote control device is optional.

Specifications

| Model No. | BUTOPOL-1000 |

| Magnetic grinding disc diameter | 250mm (optional 200mm, 230mm) |

| Sample holder | 6-hole,Φ33mm(Φ20mm, or 3-hole, Φ40-Φ50mm is optional |

| Grinding disc rotation speed | 100-1000 rpm, FWD & REV rotation directions can be switched |

| Grinding head rotation speed | 30-200 rpm, FWD & REV rotation directions can be switched |

| Manual mode | Manual mode |

| Automatic mode | 30 groups of process parameters, and each group of process includes 10 steps of procedure parameters (automatic processing from step 1 to step 10, each step has its independent group of procedure parameters). |

| Grinding head locking method | Electromagnetic automatic locking |

| Air source pressure | no less than 0.6MPa |

| Power supply | 220V, 50/60Hz, single phase, 2KW |

| Motor power | 750W |

| Overall Dimensions | 760x 470 x 700 mm |

| Net weight | 80Kg |

Accessories

- BUTOPOL-1000 : 1 Set

- Diamond suspension polishing liquid, 6 micron, 200ml : 1 Bottle

- One side sticky Abrasive paper (250mm) 180# : 2 pc

- One side sticky polishing cloth (250mm), flocking (brown) : 1 pc

- One side sticky Abrasive paper (250mm) 800# : 2 pc

- One side sticky polishing cloth (250mm), canvas : 1 pc

- One side sticky Abrasive paper (250mm) 1000# : 2 pc

- Anti-sticky disc (250mm) : 1 pc

- Waterproof ring : 1 pc

- Magnetic working plate (250mm) : 1 pc

- Input-water pipe 8mm : 1 pc

- Power cable (Aviation plug joint) : 1 pc

- Output-water pipe 25mm : 1 pc

- Data cable (Aviation plug joint) : 1 pc

- Hose hoops 18-32 : 1 pc

- Triangle valve Φ12.7mm : 1 pc

- Hook : 1 pc

- Teflon tape : 1 pc

- Rubber pad with strainer Φ12.7mm : 1 pc

- Fast twist joint SNZ08-04 : 1 pc

- Touch pen : 1 pc

- Filter piece Φ12.7mm : 4 pcs

- Technical documents : Machine manual, certificate, packing list 1 share for each.

Software Description

Download Cataloge

ENQUIRY

Automatic Metallographic Specimen Grinding & Polishing Machine

Description

Model BUTOPOL-1000XP is a kind of single disc pneumatic type automatic metallographic specimen grinding and polishing machine equipped with automatic polishing head and stepless speed changing. It features advanced performance and high degree automation and can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing automatically. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Individual samples are loaded independently.

- Central force loading of the sample disc, fix six samples at one time, complete all grinding and polishing processes, and ensure the complete plane of each sample by the grinding.

- Grinding & polishing disc and sample disc: set and run all grinding and polishing parameters, such as rotating speed, grinding and polishing time, rotation direction, water valve on/off, etc., which are automatically saved and easy to call.

- Touch screen interface: it is convenient to set grinding and polishing parameters, intuitive status display and simple operation.

- The rotation direction of both grinding & polishing disc and sample disc can be switched, and the rotation speed changing is stepless.

- Working modes:

(1) Fully automatic mode:

According to the sample materials or the habits of users, 30 sets of processes (processes) can be set and called, and each process can contain 10 process parameters (for each process, for a certain grinding or polishing process, process parameters: grinding disc and grinding head rotation speed, grinding and polishing time...)

(2) Single operation mode:

According to each grinding and polishing process, 30 process parameters can be set and called: grinding disc and grinding head rotation speed, grinding and polishing time, water on-off

(3) Manual mode:

Operate a function of the equipment separately

- Four channel automatic dispenser (optional):

(1) The main machine of the grinding and polishing machine controls the four channel dispenser. The type and speed of dispenser are controlled by the grinding and polishing machine.

(2) There are three working modes of the dispenser: manual, online and automatic.

(3) Connect the dispenser with the grinding & polishing machine and drip liquid according to the parameters set by the grinding and polishing machine. Each mode can set dripping speed and dripping time independently.

- The USB flash disk stores 300 processes, which can be imported and exported.

- Electromagnetic automatic locking of grinding head, replacing manual grinding head locking wrench, which is more convenient.

- By easily replacing the magnetic anti sticky disc, all processes such as rough and fine grinding, rough and fine polishing of various samples can be completed. One disc is equivalent to several discs.

- Mobile terminal remote control operation (optional).

Specifications

| Model No. | BUTOPOL-1000XP |

| Grinding & polishing disc diameter | 254mm (optional 230mm, 203mm) with magnetic disc |

| Grinding disc rotation speed | 50~1000 rpm (Forward and reverse rotation direction can be switched) |

| Sample disc speed | 30~200 rpm (Forward and reverse rotation direction can be switched) |

| Manual mode | 30 sets of parameters could be selected, each one can be set and called separately |

| Automatic mode | 30 sets of processes, each set of process contains 10-step parameters (from step 1 to step 10 automatically, each step has an independent setting of parameters) |

| Sample holder | Ø30mm, 6-hole (optional 20mm, 6-hole, 40mm/50mm 3-hole, or others can be customized) |

| Grinding head locking mode | Electromagnetic automatic lock |

| Working air pressure | Not less than 0.6 MPa |

| Motor power | 0.75Kw |

| Power supply | AC 220V, 50/60Hz, Single phase, 2KW |

| Dimensions & Weight | 760 x 730 x 700mm & 63kg |

Accessories

- AUTOPOL-1000XP : 1Set

- Diamond suspension polishing liquid, 6 micron, 200ml : 1Pc

- One side sticky Abrasive paper (250mm) 180# : 2Pc

- One side sticky polishing cloth (250mm), flocking (brown) : 1Pc

- One side sticky Abrasive paper (250mm) 800# : 2Pc

- One side sticky polishing cloth (250mm), canvas : 1Pc

- One side sticky Abrasive paper (250mm) 1000# : 2Pc

- Anti-sticky disc (250mm) : 2Pc

- Waterproof ring : 2Pc

- Magnetic working plate (250mm) : 2Pc

- Input-water pipe 8mm : 1Pc

- Power cable (Aviation plug joint) : 1Pc

- Output-water pipe 25mm : 1Pc

- Data cable (Aviation plug joint) : 1Pc

- Hose hoops 18-32 : 1Pc

- Triangle valve Φ12.7mm : 1Pc

- Hook : 1Pc

- Teflon tape : 1Pc

- Rubber pad with strainer Φ12.7mm : 1Pc

- Fast twist joint SNZ08-04 : 1Pc

- Touch pen : 1Pc

- Filter piece Φ12.7mm : 4Pc

- Technical documents: Machine manual, certificate, packing list 1 share for each

Software Description

Download Cataloge

ENQUIRY

Single Disc Pneumatic Type Automatic Metallographic Specimen Grinding & Polishing Machine

Description

Model BUTOPOL 2000XP is a kind of double-disc pneumatic type automatic metallographic specimen grinding and polishing machine equipped with automatic polishing head and stepless speed changing. It features advanced performance and high degree automation and can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing automatically. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Individual samples are loaded independently.

- Central force loading of the sample disc, fix six samples at one time, complete all grinding and polishing processes, and ensure the complete plane of each sample by the grinding.

- Grinding & polishing disc and sample disc: set and run all grinding and polishing parameters, such as rotating speed, grinding and polishing time, rotation direction, water valve on/off, etc., which are automatically saved and easy to call.

- Touch screen interface: it is convenient to set grinding and polishing parameters, intuitive status display and simple operation.

- The rotation direction of both grinding & polishing disc and sample disc can be switched, and the rotation speed changing is stepless.

- Working modes:

- Fully automatic mode: According to the sample materials or the habits of users, 30 sets of processes (processes) can be set and called, and each process can contain 10 process parameters (for each process, for a certain grinding or polishing process, process parameters: grinding disc and grinding head rotation speed, grinding and polishing time...)

- Single operation mode: According to each grinding and polishing process, 30 process parameters can be set and called: grinding disc and grinding head rotation speed, grinding and polishing time, water on-off

- Manual mode: Operate a function of the equipment separately

- Four channel automatic dispenser (optional):

- The main machine of the grinding and polishing machine controls the four channel dispenser. The type and speed of dispenser are controlled by the grinding and polishing machine.

- There are three working modes of the dispenser: manual, online and automatic.

- Connect the dispenser with the grinding & polishing machine and drip liquid according to the parameters set by the grinding and polishing machine. Each mode can set dripping speed and dripping time independently.

- The USB flash disk stores 300 processes, which can be imported and exported.

- Electromagnetic automatic locking of grinding head, replacing manual grinding head locking wrench, which is more convenient.

- By easily replacing the magnetic anti sticky disc, all processes such as rough and fine grinding, rough and fine polishing of various samples can be completed. One disc is equivalent to several discs.

- Mobile terminal remote control operation (optional).

Specifications

| Model No. | BUTOPOL-2000XP |

| Grinding & polishing disc diameter | 254mm (optional 230mm, 203mm) with magnetic disc |

| Grinding disc rotation speed | 50~1000 rpm (Forward and reverse rotation direction can be switched) |

| Sample disc speed | 30~200 rpm (Forward and reverse rotation direction can be switched) |

| Manual mode | 30 sets of parameters could be selected, each one can be set and called separately |

| Automatic mode | 30 sets of processes, each set of process contains 10-step parameters (from step 1 to step 10 automatically, each step has an independent setting of parameters) |

| Sample holder | Ø30mm, 6-hole (optional 20mm, 6-hole,40mm/50mm 3-hole, or others can be customized) |

| Grinding head locking mode | Electromagnetic automatic lock |

| Working air pressure | Not less than 0.6 MPa |

| Motor power | 0.75Kw |

| Power supply | AC 220V, 50/60Hz, Single phase, 2KW |

| Dimensions & Weight | 760 x 730 x 700mm & 74kg |

Accessories

- BUTOPOL 2000XP : 1 set

- Diamond suspension polishing liquid, 6 micron, 200ml : 1 Pc

- One side sticky Abrasive paper (250mm) 180# : 2 Pc

- One side sticky polishing cloth (250mm), flocking (brown) : 1 Pc

- One side sticky Abrasive paper (250mm) 800# : 2 Pc

- One side sticky polishing cloth (250mm), canvas : 1 Pc

- One side sticky Abrasive paper (250mm) 1000# : 2 Pc

- Anti-sticky disc (250mm) : 2 Pc

- Waterproof ring : 2 Pc

- Magnetic working plate (250mm) : 2 Pc

- Input-water pipe 8mm : 1 Pc

- Power cable (Aviation plug joint) : 1Pc

- Output-water pipe 25mm : 1 Pc

- Data cable (Aviation plug joint) : 1 Pc

- Hose hoops 18-32 : 1 Pc

- Triangle valve Φ12.7mm : 1 Pc

- Hook : 1 Pc

- Teflon tape : 1 Pc

- Rubber pad with strainer Φ12.7mm : 1 Pc

- Fast twist joint SNZ08-04 : 1 Pc

- Touch pen : 1 Pc

- Filter piece Φ12.7mm : 4 Pc

- Technical documents: Machine manual, certificate, packing list 1 share for each

Software Description

Download Cataloge

ENQUIRY

Automatic Metallographic Specimen Grinding & Polishing Machine

Description

Model BETAPOL-1P Automatic Metallographic specimen grinding and polishing machine is equipped with independent powered polishing head and features stepless speed changing It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Single pressure specimen holding

- Illuminated led indication display functioning with digital timer

- Variable time and RPM setting

- Disc movement can be clockwise/counter clockwise

- Sound rating less than 75 dB at maximum RPM.

- Easy start stops smooth function.

Specifications

| Model No. | BETAPOL-1P |

| Diameter of working disc | Ø200mm (Minimum) |

| No of polishing Disc | Single |

| Rotating speed of working disc | 600 rpm (Maximum) |

| Rotating speed of polishing head | Stepless speed changing upto 100 rpm |

| Sample holder (Minimum 3 samples) | 30mm-50mm |

| Sample preparing time | 60-999 seconds |

| Operating temperature | 10⁰-40⁰C |

| Torque motor | 1 HP |

| Polishing Head motor | ½ HP |

| Power supply | Single phase, 220V, 50Hz |

Accessories

Software Description

Download Cataloge

ENQUIRY

Automatic Metallographic Specimen Grinding & Polishing Machine With Head

Description

Model BETAPOL-1000P is a kind of pneumatic type automatic metallographic specimen grinding and polishing machine equipped with automatic polishing head and features stepless speed changing and four-level constant speed for grinding and polishing. The working time can be preset and the rotating direction can be controlled. It can finish the whole process of rough grinding, fine grinding, rough polishing and finishing polishing for specimen preparing. It is the necessary metallographic specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Application

Features

- Six pieces Φ30mm samples can be grinded and polished simultaneously.

- Both grinding disc and polishing head adopt stepless speed control, and the rotating direction of grinding disc can be shifted.

- Pneumatic single point loading, fix the sample and then it can complete the whole process of grinding and polishing, and this can ensure the plane parallelism of sample.

- Working time and rotating speed presetting

- Quick exchanging disc. The working disc can be changed and replaced swiftly.

- Equipped with magnetic disc and anti-sticky disc which is very convenient for quick changing of abrasive paper and polishing cloth.

Specifications

| Model No. | BETAPOL-1000P |

| Rotating speed of working disc | 250mm (200mm or 300mm is optional) |

| Rotating speed of polishing head | stepless speed changing 50-1000 rpm, and four level constant speed of 200 / 600 / 800 / 1000 rpm |

| Rotating speed of polishing head | stepless speed changing 5-150 rpm (5-200 rpm optional) |

| Sample holder | Φ30mm, 6-hole (or customized) |

| Loading force range | 5-60N |

| Sample preparing time | 0-9999 seconds |

| Power supply | Single phase, 220V, 50Hz |

| Motor power | 750W |

| Dimensions | 760 x 480 x 700 mm |

| Net weight | 70 Kg |

Accessories

Software Description

Download Cataloge

ENQUIRY

Automatic Metallographic Specimen Grinding & Polishing Machine

Description

In the process of metallographic sample preparation, the grinding and polishing of the sample is an indispensable process. After the sample is ground and polished, a bright mirror-like surface can be obtained. The BMP-2TW automatic metallographic sample grinding and polishing machine adopts high quality touch screen control, one time can process 3 pieces of samples, adjustable stepless speed between 50-1000r/min. The grinding and polishing of the sample can be completed by replacing the metallographic sandpaper and polishing fabric. It is especially suitable for metallographic laboratories in factories, colleges and research institutes, and is an excellent equipment for grinding polishing metallographic samples.

Application

Features

- Touch screen with menu structure, operate very easy.

- Double working plates φ230mm, greatly improved working efficiency.

- Stepless speed 50-1000rpm + 6 constant speed design, setting speed more easier.

- By Weights loading pressure on sample, one time can automatic process 3 pieces of samples (Ø30mm).

- Multi-usage, metallographic specimen of coarse grinding, fine grinding, coarse and fine polishing, one machine to complete.

- Support different rotating direction: counterclockwise and clockwise.

- The appearance of this machine is classic and beautiful. The outer casing is made of thickened sheet metal spray-plastic process, and the dirt collecting tray is integrally made of thickened ABS plastic process. The machine is durable and easy to maintain.

- The motor of this machine adopts a full copper coil motor, which has stable rotation, low noise and long life.

- The water faucet is made of all copper, which has good hand feel, long life and does not rust.

- This machine uses a vector frequency converter with sufficient power and a large speed range to adapt to different speed requirements during the sample preparation process.

Specifications

| Model No. | BMP-2TW |

| No. of polishing disc | Double disc |

| Working disc | Standard φ200mm |

| Speed of working disc | 50-1000 r/min (and 6 constant speed) Support clockwise / anticlockwise direction rotating |

| Grinding head speed | 60 r/min |

| Sample holder | Standard φ30mm 3 pieces of samples |

| Pressure loading type | By dead weights loading pressure, mechanical structure, durable working performance |

| Power supply | Single Phase, AC220V, 50Hz, 1300W |

| Machine size (L*W*H) & N/W | 72X67X45cm, 60kg |

| Package size & G/W | 82x72x70cm, 85kg |

Accessories

- BMP-2TW: 1pc

- Polishing cloth (230mm): 1pc

- Sandpaper (230mm): 1pc

- Waterproof ring: 2pcs

- Press ring: 2pcs

- Water outlet pipe: 1pc

- Water inlet: 1pc

- Power line: 1pc

Software Description

Download Cataloge

ENQUIRY

Touch Screen Automatic Metallographic Specimen Grinding & Polishing Machine

Description

In the process of metallographic sample preparation, the grinding and polishing of the sample is an indispensable process. After the sample is ground and polished, a bright mirror-like surface can be obtained. The metallographic sample grinding and polishing machine adopts a frequency converter to adjust the speed, which can make the speed of the grinding and polishing disc infinitely adjustable between 50-1000r/min. The grinding and polishing of the sample can be completed by replacing the metallographic sandpaper and polishing fabric. It is especially suitable for metallographic laboratories in factories, colleges and research institutes, and is an excellent equipment for grinding polishing metallographic samples.

Application

Features

- One machine can do the rough grinding, fine grinding, rough polishing and fine polishing of metallographic specimens.

- Double working plates φ250mm, double times improved working efficiency.

- Pneumatic version automatic grinding head, one time can process 4 pieces of samples.

- Integral moulding of high-strength FRP material shell, sturdy and durable, never rusty.

- The faucet adopts copper material, which has good corrosion resistance.

- Stepless speed design, low noise, stable working performance. We can meet a variety of needs.

- With water cooling system to prevent damage to the metallographic structure due to overheating of the sample. And can get better metallographic surface easily.

Specifications

| Model No. | BGPM-3A |

| No. of polishing disc | Single disc |

| Grinding polishing plate diameter | φ250mm (optional φ203mm, 230mm) |

| Sample number | 4 pieces φ30mm sample |

| Disc rotate speed | 50-1000r/min (stepless adjustable) and 4 constant speed (400rpm, 600rpm, 800rpm, 1000rpm) |

| Automatic grinding head | 5-150 rpm (stepless speed) |

| Sample holding type | Single point pressure loading |

| Force loading | Pneumatic (should work with air compressor) |

| Loading force range | 0-0.7Mpa (factory setting is less than 0.2MPa) |

| Motor power | 0.9KW |

| Machine size (L*W*H) & N/W | 55*785*700mm, 70kg |

| Package size & G/W | 950*680*870mm, 90kg |

| Power supply | Single phase, AC 220V 50Hz |

Accessories

- Grinding plate Φ250 (on machine): 1pc

- Water inlet pipe + Water outlet pipe: 1pc + 1pc

- Water retaining ring (on machine): 1pc

- Level adjust screw: 4pcs

- Abrasive paper φ250: 2pcs

- Power cord: 1pc

- Polishing cloth φ250: 2pcs

- Anti-dust lid: 1pc

- waterproof ring: 1pc

- Magnetic disc: 1pc

- Pressure-resistant tube φ8: 1pc

- Anti-stick disc: 3pcs

- Oil-water separator: 1pc

- Manual: 1pc

- Certificate: 1pc

Software Description

Download Cataloge

ENQUIRY

Single Disc Automatic Metallographic Sample Grinding & Polishing Machine

Description

In the process of metallographic sample preparation, the grinding and polishing of the sample is an indispensable process. After the sample is ground and polished, a bright mirror-like surface can be obtained. The metallographic sample grinding and polishing machine adopts a frequency converter to adjust the speed, which can make the speed of the grinding and polishing disc infinitely adjustable between 50-1000r/min. The grinding and polishing of the sample can be completed by replacing the metallographic sandpaper and polishing fabric. It is especially suitable for metallographic laboratories in factories, colleges and research institutes, and is an excellent equipment for grinding polishing metallographic samples.

Application

Features

- One machine can do the rough grinding, fine grinding, rough polishing and fine polishing of metallographic specimens.

- Double working plates φ250mm, double times improved working efficiency.

- Pneumatic version automatic grinding head, one time can process 6 pieces of samples.

- Integral moulding of high-strength FRP material shell, sturdy and durable, never rusty.

- The faucet adopts copper material, which has good corrosion resistance.

- Stepless speed design, low noise, stable working performance. We can meet a variety of needs.

- With water cooling system to prevent damage to the metallographic structure due to overheating of the sample. And can get better metallographic surface easily.

Specifications

| Model No. | BGPM-3B |

| No. of polishing disc | Double disc |

| Grinding polishing plate diameter | φ250mm (optional φ230mm, 300mm) |

| Sample number | 6 pieces φ30mm sample |

| Disc rotate speed | 50-1000r/min (stepless adjustable) and 4 constant speed (400rpm, 600rpm, 800rpm, 1000rpm) |

| Automatic grinding head | 5-150 rpm (stepless speed) |

| Sample holding type | Single point pressure loading |

| Force loading | Pneumatic (should work with air compressor) |

| Loading force range | 0-0.7Mpa (factory setting is less than 0.2MPa) |

| Motor power | 0.9KW |

| Machine size (L*W*H) & N/W | 790*740*700mm, 90kg |

| Package size & G/W | 920*820*840mm, 115kg |

| Power supply | Single phase, AC 220V 50Hz |

Accessories

- Grinding plate Φ250 (on machine): 2pcs

- Water inlet pipe + Water outlet pipe: 1pc + 1pc

- Water retaining ring (on machine): 2pcs

- Level adjust screw: 4pcs

- Abrasive paper φ250: 2pcs

- Power cord: 1pc

- Polishing cloth φ250: 8pcs

- Anti-dust lid: 2pcs

- Waterproof ring: 2pcs

- Magnetic disc: 2pcs

- Pressure-resistant tube φ8: 1pc

- Anti-stick disc: 5pcs

- Oil-water separator: 1pc

- Manual: 1pc

- Certificate: 1pc

Software Description

Download Cataloge

ENQUIRY

Double Disc Automatic Metallographic Specimen Grinding & Polishing Machine

Description

In the process of metallographic sample preparation, the grinding and polishing of the sample is an indispensable process. After the sample is ground and polished, a bright mirror-like surface can be obtained. The BGP-2TA automatic metallographic sample grinding and polishing machine adopts high quality touch screen control, adjustable stepless speed between 50-1000r/min. The grinding and polishing of the sample can be completed by replacing the metallographic sandpaper and polishing fabric. It is especially suitable for metallographic laboratories in factories, colleges and research institutes, and is an excellent equipment for grinding polishing metallographic samples.

Application

Features

- Touch screen with menu structure, operate very easy.

- Multi-usage, metallographic specimen of coarse grinding, fine grinding, coarse and fine polishing, one machine to complete.

- Stepless speed 50-1000rpm + 8 constant speed design, setting more easier.

- Easily manual replace magnetic anti-sticking disc, can make all kinds of sample of coarse and fine grinding, coarse and fine polishing all process (optional purchase).

- Support different rotating direction: counterclockwise and clockwise.

- Double working plates φ250mm, greatly improved working efficiency.

- Two working plates can working independently.

Specifications

| Model No. | BGP-2TA |

| No. of polishing disc | Double disc |

| Working disc | Standard φ200mm |

| Speed of working disc | 50-1000 r/min (and 8 constant speed) Support clockwise / anticlockwise direction rotating |

| Grinding head speed | 50 r/min |

| Sample holder | Standard φ30mm 4 pieces of samples |

| Pressure loading type | By spring mechanical loading pressure |

| Power supply | AC220V, 50Hz, 0.9KW |

| Machine size (L*W*H) & N/W | 770X730X530mm, 60kg |

| Package size & G/W | 860X810X720mm, 78kg |

Accessories

- BGP-2TA: 1pc

- Polishing cloth (250mm): 1pc

- Sandpaper (250mm): 1pc

- Waterproof ring: 4pcs

- Press ring: 2pcs

- Water outlet diameter 32mm: 1pc

- Water inlet: 1pc

- Power line: 1pc

Software Description

Download Cataloge

ENQUIRY

Touch Screen Automatic Metallographic Specimen Grinding & Polishing Machine